arunvenkats

Member

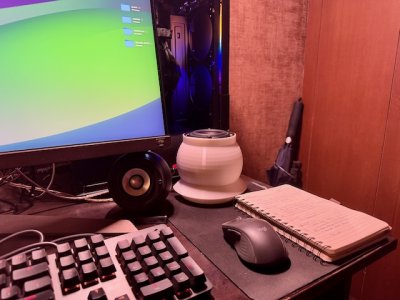

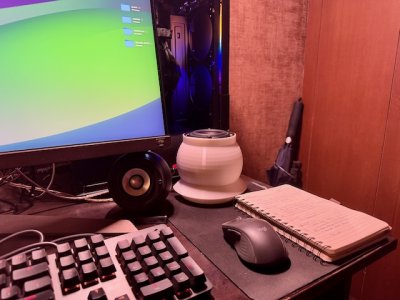

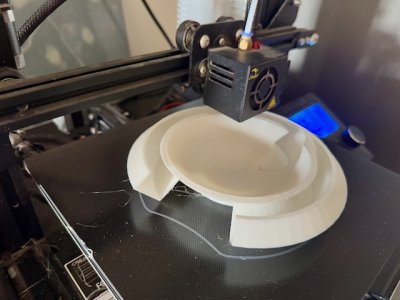

After I finished the 3" Oblate spheroid full range speakers [https://www.hifivision.com/threads/oblate-spheroid-3d-printed-near-field-speaker.97826], realised that it lacked bass. As expected though, they are tiny 3" full range drivers. Decided to add some bass to the setup. Ordered a Peerless SLS-85S25CP04-04 3-1/2″ Paper Cone Woofer and built a 3D printed ported enclosure for it. The results were far better than what I expected for a 3D printed woofer enclosure. Matches perfectly with the full range speakers. I am driving it through a cheap 2.1 amplifier and more than happy with the outcome for casual, background music for work. Love the sweet, smooth bass at low volumes.

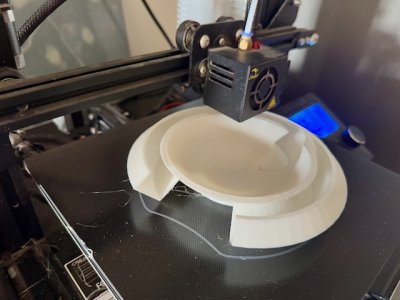

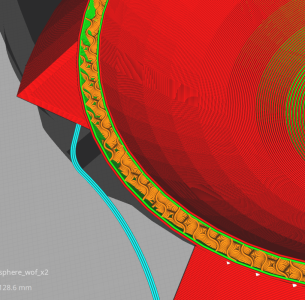

Don't laugh at the shape! It is a design where pure function-over-form was chosen. The sphere is the smallest surface area for a given volume. This means it uses less material and finishes printing faster. It took a day and 6 hours to print this. The port tube is a square cross section and placed 45° rotated to make sure there are no supports which need to be printed. It would be impossible to remove 3D printing supports from within the tube...

Designing a port which can be 3D printed without supports was tricky but a worthy experience

One side of the port tube is dummy, just acting as a stand for the speaker. It is not connected to the internal chamber.

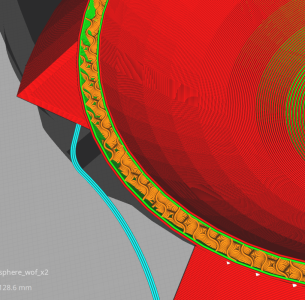

The infill for the wall -- I chose "gyroid" which I believe is giving good insulation.

Sounds great for ₹2K investment on the driver. The 3D printing does not cost much if you have your own printer. Just around ₹240 for the material in this case.

Regards,

Arun

Don't laugh at the shape! It is a design where pure function-over-form was chosen. The sphere is the smallest surface area for a given volume. This means it uses less material and finishes printing faster. It took a day and 6 hours to print this. The port tube is a square cross section and placed 45° rotated to make sure there are no supports which need to be printed. It would be impossible to remove 3D printing supports from within the tube...

Designing a port which can be 3D printed without supports was tricky but a worthy experience

One side of the port tube is dummy, just acting as a stand for the speaker. It is not connected to the internal chamber.

The infill for the wall -- I chose "gyroid" which I believe is giving good insulation.

Sounds great for ₹2K investment on the driver. The 3D printing does not cost much if you have your own printer. Just around ₹240 for the material in this case.

Regards,

Arun