FlaCharlie

Active Member

So a few years ago I picked up a Switch Mode Power Supply (SMPS) that's designed for tube circuits. It has separate outputs for 6.3v and 12.6v heaters and a 300v output for the B+. But other projects took precedence so it sat on the shelf for a long time. Some folks over at DIYAudio had messed around with them with varying results. I culled as much info as I could from them and I finally got around to using it on my breadboard setup to power a basic SE circuit. The obvious attractions are low cost and simplicity.

This piqued my interest in extending that element of simplicity to the rest of the amp. I get the sense that there are a lot of folks who might be interested in building a DIY tube amp but are hesitant to take the plunge because they are overwhelmed by the complexity. My goal here is to present something that is far less intimidating for newbies.

This is a project that anyone CAN build. Not just a simple circuit but something that is extremely easy to assemble while still using point to point wiring.

So I've dubbed this one the Simplissimo. I'm not sure if that's a real word or not but I like it.

The result is a design whose construction requires no soldering. You can build this amp with a screwdriver and a few basic hand tools. It's nothing earth shattering. The same construction techniques are commonly used when breadboarding which is the experimental process I always use when I build a DIY project from scratch. It's a simple technique where all the parts are mounted to a wooden board. So no chassis fabrication skills are needed either.

My breadboard experiments always end up looking like a rat's nest with so many clip leads running everywhere that it's scary. So I've eliminated that aspect. And while my experiments typically do have some soldered connections, this just takes the next step and eliminates them. I plan on posting a few designs that use breadboard style construction and this SMPS.

Just to be clear, this build isn't so much about using a particular tube or circuit. I'm just using this SMPS as a turn-key power supply solution and combining it with simplified build techniques. Any design that can be powered with ~300v B+ can be built like this and it's easy to experiment since everything is wired point to point. Want to compare pentode, triode and UL? Try a boutique coupling cap? A different feedback resistor value? A different biasing method? A screwdriver is all you need.

Of course, if a more traditional build is preferred, the same construction techniques can be combined with a conventional power supply and some type of chassis. Eventually, I'll be posting a different circuit that combines these breadboard techniques and SMPS with the same type of bamboo box that I used for a chassis with my Boogie Factor 1626 preamp.

www.hifivision.com

www.hifivision.com

Those who have read my previous build threads know that I like to keep costs low by using repurposed materials and I often use inexpensive, "under the radar", tubes. I've strayed from that formula just a bit here in that this design uses tubes that are common and in current production.

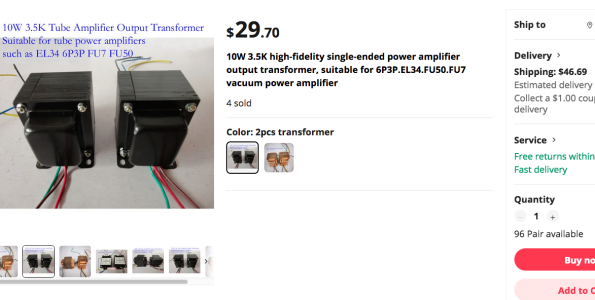

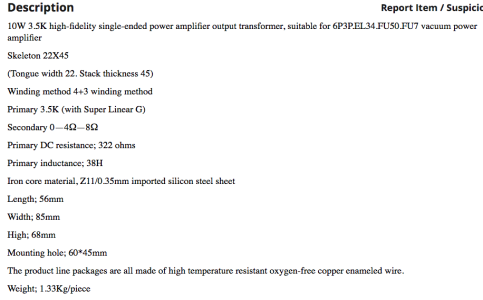

I have not abandoned the low budget, bang for the buck, approach. You should be able to build it for ~$300 if you forego the use of boutique coupling caps. A considerably less expensive version could be built if you go with a SE circuit that runs 6V6s or 12V6s in triode or pentode (not UL) that uses less expensive output transformers.

I'm not a designer or an engineer. I'm just a hobbyist / copy and paste builder. I try to incorporate elements from other designs and combine them in different ways. There are many popular SE circuits out there which use a triode to drive a variety of output tubes. So you'll find many of the same elements I'm using here elsewhere. Truth is, there's not much new under the sun when it comes to tube amps.

For simplicity I decided to stick with octal tubes only and to save space I opted to use a single, dual triode, input tube. So I experimented with both the 6SN7 or 6SL7 as inputs in combination with numerous output tubes including the 6V6, EL34, 6L6GC, the Russian 6n3ce and the 7591. I tried running triode, pentode, UL and E-Linear, though not all combinations with every different tube. I also tried a variety of biasing methods for the input tube and some other circuit variations.

In the end I chose the EL34 which offers a good combination of power and affordability with a 6SL7 on the input. No, I haven't abandoned the use of oddball tubes and the versions that follow will likely use some.

Building the same circuits over and over again is not my style. I usually try to incorporate at least a few "new to me" elements in my DIY projects. Gotta keep it fresh and interesting.

Although I have some vintage PP EL34 amps that I've restored, I've never built anything from scratch with an EL34 or a 6SL7. I've also never built an Ultra Linear (UL) amp or anything that uses local, plate-to-plate (aka Schade), feedback. And, though I used SMPSs to heat the tubes in my most recent amp, the Cockeyed Monkey, the use of a SMPS to power everything is also new to me.

https://www.hifivision.com/threads/glotone-cockeyed-monkey-a-directly-coupled-set.94233/

The output section is just a basic UL EL34 design using local, plate-to-plate (aka Schade), feedback. The current popularity of Schade FB is often traced to the RH amp designs but it's really nothing new. I recently came across a schematic for a "house brand" radio that was sold in Western Auto stores starting in 1947. It uses Schade FB in its amplifier section, which consists of a 6SQ7 driving a 6V6 output tube.

This basic output section is now very common. One example is the Skunkie Designs EL34 amp. She is now selling handcrafted, custom built amps using the same basic output section for ~$2000 to $2500. The most expensive version uses the legendary ISO Tango OTs! Of course she also has a series of step-by-step videos on her YouTube channel for those who want to build it themselves.

And Analog Ethos sells SE EL34 kits using the same UL output section design for ~$1300 to $1600. Their instructions are superb and this is a great option for those who would rather not deal with chassis fabrication. I've also seen some schematics that use the same circuit with different output tubes, such as the 6V6. So the basic design is well known and respected.

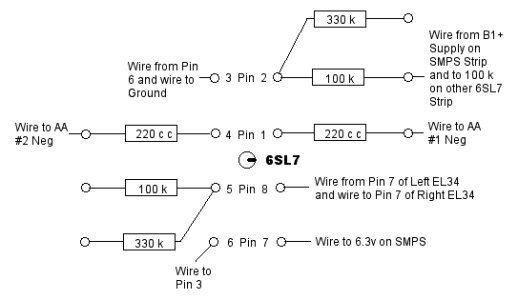

For the input I'm using the 6SL7, which is a dual triode. And just like the amps mentioned above, I'm using one triode to drive each EL34.

Besides the use of a SMPS and breadboard construction techniques there are two main differences between the designs mentioned and this one. The most obvious one is that this PS only puts out ~300v, so I'm running the outputs at lower voltage and higher current while the others run higher voltage and lower current.

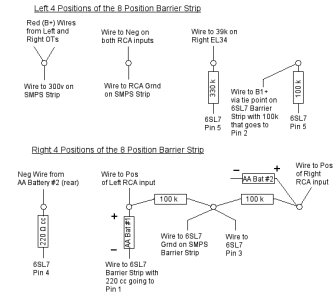

The other is that I use a AA battery to bias the 6SL7. I've used the same battery grid bias scheme for input tubes in other builds too. It's simple to implement and I like how it sounds. Because the tube does not draw current from the battery, the battery will last as long as its shelf life. For a common Alkaline that should be at least 3 to 4 years. For a lithium it's probably 8 to 10 years. You must use regular batteries in this application. You can not use rechargeables.

Of course you can try other bias schemes. For example, Stephe's Skunkie Designs amp uses a combination of a resistor and an LED to bias the dual triode 5751 input tube in her amp. The 5751 is a 9 pin miniature that has the same amplification factor (mu 70) as the 6SL7, BTW. The Analog Ethos kit uses the more traditional combination of a cathode resistor and bypass cap to bias a dual triode 12AT7, another 9 pin miniature.

I tried both of these alternatives and preferred the battery method but YMMV. I encourage prospective builders to take full advantage of the breadboard and point-to-point construction methods used here. Break out the screwdriver and experiment!

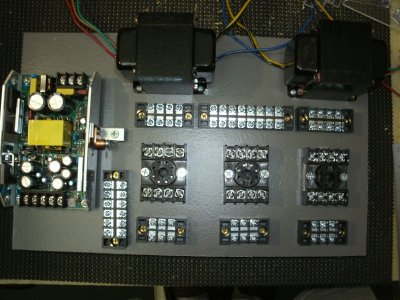

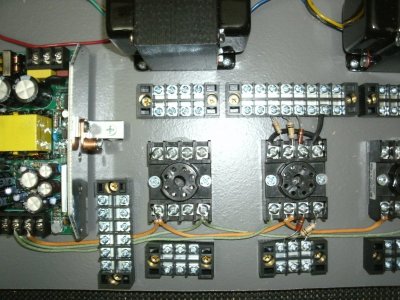

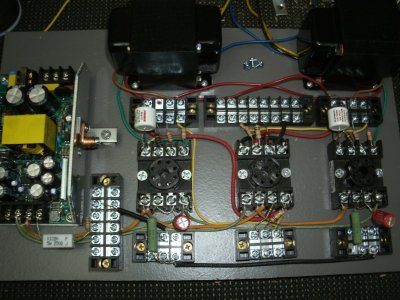

Anyway, here's a pic of the finished amp. Yeah, it's not much to look at:

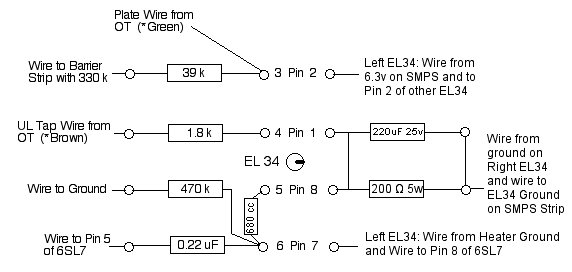

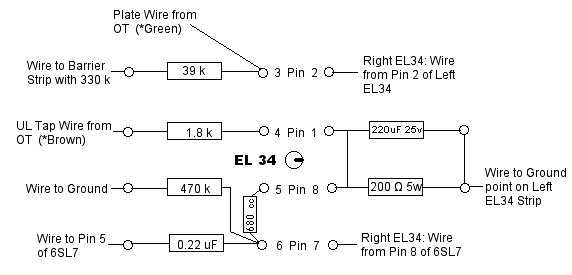

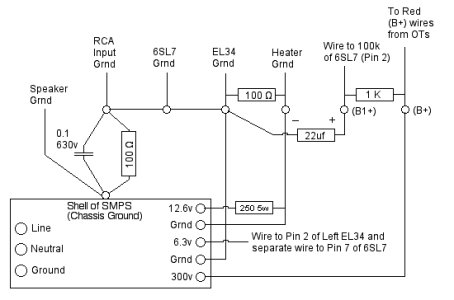

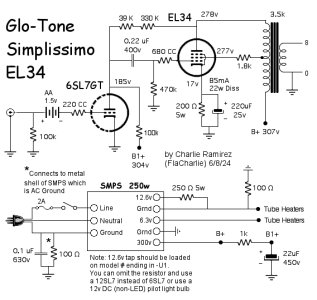

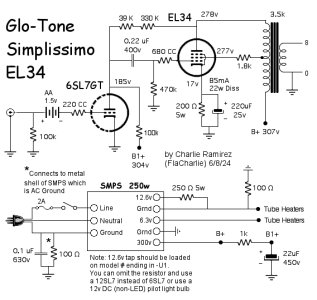

And here's the schematic:

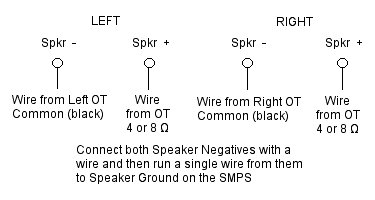

Since most people who can't solder or fabricate a chassis probably can't read and build from a schematic either, I'll add some (hopefully) easy to follow wiring diagrams, a few in-progress pics and some construction notes, along with a basic parts list later. Oh, and if you're concerned about using breadboard construction because of the high voltages that are present, that will be addressed too. I'll do my best to try to present all this in a newbie friendly manner.

Again, my goal here is to encourage people to get into the DIY aspect of this hobby we all enjoy.

If you're DIY curious I encourage you to check out the excellent Skunkie Designs videos (as well as other build channels) on YouTube, the kits available from Analog Ethos and others, as well as threads on other forums, such as Audio Karma, that focus on restoring and modding amps pulled from old console stereos. What I'm presenting here is just another "intro to DIY" option.

This piqued my interest in extending that element of simplicity to the rest of the amp. I get the sense that there are a lot of folks who might be interested in building a DIY tube amp but are hesitant to take the plunge because they are overwhelmed by the complexity. My goal here is to present something that is far less intimidating for newbies.

This is a project that anyone CAN build. Not just a simple circuit but something that is extremely easy to assemble while still using point to point wiring.

So I've dubbed this one the Simplissimo. I'm not sure if that's a real word or not but I like it.

The result is a design whose construction requires no soldering. You can build this amp with a screwdriver and a few basic hand tools. It's nothing earth shattering. The same construction techniques are commonly used when breadboarding which is the experimental process I always use when I build a DIY project from scratch. It's a simple technique where all the parts are mounted to a wooden board. So no chassis fabrication skills are needed either.

My breadboard experiments always end up looking like a rat's nest with so many clip leads running everywhere that it's scary. So I've eliminated that aspect. And while my experiments typically do have some soldered connections, this just takes the next step and eliminates them. I plan on posting a few designs that use breadboard style construction and this SMPS.

Just to be clear, this build isn't so much about using a particular tube or circuit. I'm just using this SMPS as a turn-key power supply solution and combining it with simplified build techniques. Any design that can be powered with ~300v B+ can be built like this and it's easy to experiment since everything is wired point to point. Want to compare pentode, triode and UL? Try a boutique coupling cap? A different feedback resistor value? A different biasing method? A screwdriver is all you need.

Of course, if a more traditional build is preferred, the same construction techniques can be combined with a conventional power supply and some type of chassis. Eventually, I'll be posting a different circuit that combines these breadboard techniques and SMPS with the same type of bamboo box that I used for a chassis with my Boogie Factor 1626 preamp.

Glo-Tone Boogie Factor 1626 Tube Preamp

I mentioned this preamp in the thread about Class D amps and a couple of people seemed interested so this thread will offer some details. What I'll do here is to present an updated version of a thread I posted elsewhere in 2020, when I built this. Some background: I first got interested in...

Those who have read my previous build threads know that I like to keep costs low by using repurposed materials and I often use inexpensive, "under the radar", tubes. I've strayed from that formula just a bit here in that this design uses tubes that are common and in current production.

I have not abandoned the low budget, bang for the buck, approach. You should be able to build it for ~$300 if you forego the use of boutique coupling caps. A considerably less expensive version could be built if you go with a SE circuit that runs 6V6s or 12V6s in triode or pentode (not UL) that uses less expensive output transformers.

I'm not a designer or an engineer. I'm just a hobbyist / copy and paste builder. I try to incorporate elements from other designs and combine them in different ways. There are many popular SE circuits out there which use a triode to drive a variety of output tubes. So you'll find many of the same elements I'm using here elsewhere. Truth is, there's not much new under the sun when it comes to tube amps.

For simplicity I decided to stick with octal tubes only and to save space I opted to use a single, dual triode, input tube. So I experimented with both the 6SN7 or 6SL7 as inputs in combination with numerous output tubes including the 6V6, EL34, 6L6GC, the Russian 6n3ce and the 7591. I tried running triode, pentode, UL and E-Linear, though not all combinations with every different tube. I also tried a variety of biasing methods for the input tube and some other circuit variations.

In the end I chose the EL34 which offers a good combination of power and affordability with a 6SL7 on the input. No, I haven't abandoned the use of oddball tubes and the versions that follow will likely use some.

Building the same circuits over and over again is not my style. I usually try to incorporate at least a few "new to me" elements in my DIY projects. Gotta keep it fresh and interesting.

Although I have some vintage PP EL34 amps that I've restored, I've never built anything from scratch with an EL34 or a 6SL7. I've also never built an Ultra Linear (UL) amp or anything that uses local, plate-to-plate (aka Schade), feedback. And, though I used SMPSs to heat the tubes in my most recent amp, the Cockeyed Monkey, the use of a SMPS to power everything is also new to me.

https://www.hifivision.com/threads/glotone-cockeyed-monkey-a-directly-coupled-set.94233/

The output section is just a basic UL EL34 design using local, plate-to-plate (aka Schade), feedback. The current popularity of Schade FB is often traced to the RH amp designs but it's really nothing new. I recently came across a schematic for a "house brand" radio that was sold in Western Auto stores starting in 1947. It uses Schade FB in its amplifier section, which consists of a 6SQ7 driving a 6V6 output tube.

This basic output section is now very common. One example is the Skunkie Designs EL34 amp. She is now selling handcrafted, custom built amps using the same basic output section for ~$2000 to $2500. The most expensive version uses the legendary ISO Tango OTs! Of course she also has a series of step-by-step videos on her YouTube channel for those who want to build it themselves.

And Analog Ethos sells SE EL34 kits using the same UL output section design for ~$1300 to $1600. Their instructions are superb and this is a great option for those who would rather not deal with chassis fabrication. I've also seen some schematics that use the same circuit with different output tubes, such as the 6V6. So the basic design is well known and respected.

For the input I'm using the 6SL7, which is a dual triode. And just like the amps mentioned above, I'm using one triode to drive each EL34.

Besides the use of a SMPS and breadboard construction techniques there are two main differences between the designs mentioned and this one. The most obvious one is that this PS only puts out ~300v, so I'm running the outputs at lower voltage and higher current while the others run higher voltage and lower current.

The other is that I use a AA battery to bias the 6SL7. I've used the same battery grid bias scheme for input tubes in other builds too. It's simple to implement and I like how it sounds. Because the tube does not draw current from the battery, the battery will last as long as its shelf life. For a common Alkaline that should be at least 3 to 4 years. For a lithium it's probably 8 to 10 years. You must use regular batteries in this application. You can not use rechargeables.

Of course you can try other bias schemes. For example, Stephe's Skunkie Designs amp uses a combination of a resistor and an LED to bias the dual triode 5751 input tube in her amp. The 5751 is a 9 pin miniature that has the same amplification factor (mu 70) as the 6SL7, BTW. The Analog Ethos kit uses the more traditional combination of a cathode resistor and bypass cap to bias a dual triode 12AT7, another 9 pin miniature.

I tried both of these alternatives and preferred the battery method but YMMV. I encourage prospective builders to take full advantage of the breadboard and point-to-point construction methods used here. Break out the screwdriver and experiment!

Anyway, here's a pic of the finished amp. Yeah, it's not much to look at:

And here's the schematic:

Since most people who can't solder or fabricate a chassis probably can't read and build from a schematic either, I'll add some (hopefully) easy to follow wiring diagrams, a few in-progress pics and some construction notes, along with a basic parts list later. Oh, and if you're concerned about using breadboard construction because of the high voltages that are present, that will be addressed too. I'll do my best to try to present all this in a newbie friendly manner.

Again, my goal here is to encourage people to get into the DIY aspect of this hobby we all enjoy.

If you're DIY curious I encourage you to check out the excellent Skunkie Designs videos (as well as other build channels) on YouTube, the kits available from Analog Ethos and others, as well as threads on other forums, such as Audio Karma, that focus on restoring and modding amps pulled from old console stereos. What I'm presenting here is just another "intro to DIY" option.