arunvenkats

Active Member

Hi folks,

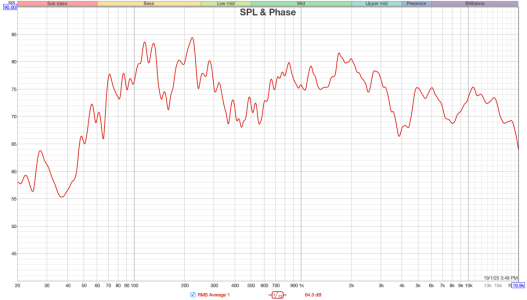

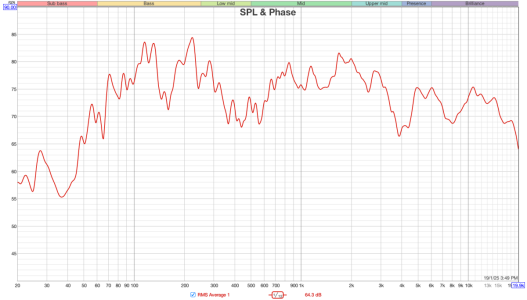

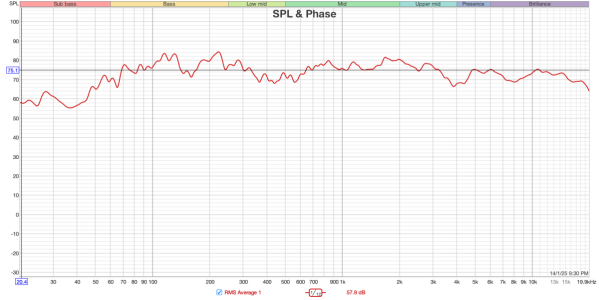

Happy to present my first serious audio project. A DIY Speaker build. After a couple of months of design, and couple of weeks of sourcing and building the speaker is ready. The speaker itself was ready 3 weeks back, but was waiting for the Dayton calibrated mic to arrive to do an objective measurement. Got the results now, what do you think? Of course the SPL chart is not really the speaker performance alone, it is the speaker+room combination. Recorded at 75dB. Comments and suggestions are most welcome.

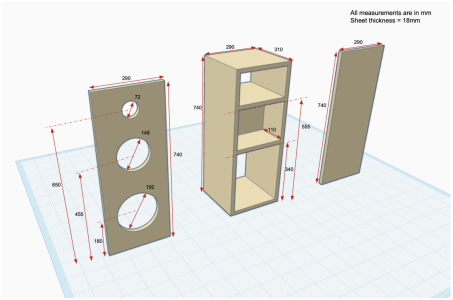

The design is a sealed unit. I do not have the time to tune a port so stuck with a sealed design. It started of as a 2 way system but eventually became a 3 way. The midrange is actually a midwoofer which I had already bought for the 2 way. But it worked out well. Peerless 1" tweeter + Peerless 6.5" mid woofer + 8" Peerless Woofer. The crossover was built with cutoffs at 300 Hz and 4000 Hz. The cabinet was built with 19mm MDF and finished with mica to suit my living room. I chose high sensitivity drivers for the tweeter and mid woofer (originally it was to be 2 way design) so that my small Fossi amp could drive them. Later on, I had to attenuate them in the crossover to match the woofer.

It ended up exceeding my expectations! Thoughts and comments most welcome.

Regards,

Arun