reubensm

Well-Known Member

changed couple of thyristor, Relay & Op amp in protection circuit along with some caps which were not matching to factory specifications

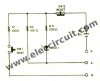

Yes, this was an amp that was worked on before. Earlier techs may not have used temperature controlled soldering. NAD amplifier PCBs tend to be very delicate and are easily damaged. Another common issue is breaks in the circuit caused by microscopic aberrations on the PCB. I checked all the PCBs in the amp, inside out under a magnifying glass, using a spot lamp and noticed some breaks here and there, had these repaired. Then started with the PSU board, this had been recapped with high quality caps but I did not want to take a chance so re-soldered the entire board properly. With the experience from an earlier NAD restoration job, thought I'll check the thyristors for performance, so took them out and built a little circuit based on the one below:

Did a probability test for each thyristor, ideally when sw1 is engaged, the thyristor should activate and the LED should glow. The LED should remain on even if sw1 is disengaged, until sw2 is disengaged and the circuit reset. Did this test 100 times for each thyristor and the LED glowing retention after disengaging sw1 was 41 for the first thyristor and 78 for the second thyristor, when ideally it should have been 100. Hence changed both thyristors. Fixes are usually tricky if the components do not fail completely and are functioning intermittently. These suspects are better tested outside the mother circuit. This is an important lesson which I learnt from my father's electronics expertise.

Now that we had a 100% working PSU board, I turned my attention to the main PCB. I noticed that the amp had been worked on previously and some key components were previously replaced, including the speaker relay. After running a comprehensive check and fixing a few PCB breaks in circuit, started with the output stage and worked my way backwards. An immediate suspect was the speaker relay. The relay on the PCB was not an original NAD relay, but a Chinese DPST replacement. Electrically, the relay checked ok and appeared to be click-switching, but on careful examination, I noticed that the resistance of the relay coil was measuring only 10 ohms, whereas the actual resistance should be in the range of 1.2k. This indicated an obvious short in the relay coil. I had two high quality DPDT mono block relays with me, gold plated and heavy duty, more like the types used in washing machines, etc. I replaced the NAD relay with these mono blocks by wiring only the relevant parts of each relay. Of course, this was a magnificent fix as these relays were high quality ones and would have lasted forever. I had mentioned this to FM Jmascreen in my regular updates but then noticed that almost immediately thereafter, most of our conversations started featuring the speaker relay. I felt he was not comfortable with Mono Block relays replacing the original relay type while I knew that these were a great replacement. However I was also sensitive to the owner side of the story and meanwhile by brother asked for the relays anyways, for his Luxman amp, hence I eventually removed these Mono Blocks and used a replacement relay, matching the specs of the original NAD speaker relay. Then turned my attention to eventually checking all the transistors in the amplifier section, and found all of them to be good. Also did a comprehensive check on the capacitor values on the board and noticed a few of them did not match those mentioned in the service manual. Replaced these with the original value electrolytics. Then moved to the protection circuitry which was not easy. Nad PCB designs are usually done in such a way that parts of the protection circuitry are spread all over the main PCB and some even in the PCB mounted behind the faceplate. After a lot of tracing and checking, noted that the protection switch, C1237HA was not functioning properly. Again, I had a Chinese speaker protection PCB available so I was able to take this IC out of the NAD PCB, put it in the Chinese PCB and test it. By this way, I easily found out that the NAD's C1237HA had to be replaced. The Chinese PCB looks similar to this one:

After changing this IC, I also checked the dual OP amp, TL082CP, noticed that it too was showing some abnormal pin voltages, especially on pins 1 and 7, took this out, soldered a 8-pin IC socket into the board and then plugged in a replacement. IC sockets are quite handy as they often accord the user with the privilege of changing ICs without having to de-solder and solder. Also changed some key filter caps and a few capacitors and a zener in the protection circuit and tested the amp. It fired and started singing immediately. I then noticed that a 1k resistor in the volume motor control regulator circuit was completely blackened and running hot. This is normal for NAD amps, so I just upgraded the existing 1/4 watt resistor to a 1.5 watt resistor for improving tolerance. Did a complete check on bias and calibrated the same with a few checks and changes, also calibrated the idle current and dc off set for both channels using NAD's factory specs for the C320. Finally noticed that the volume motor was not functioning and traced this down to a blown C1015 transistor in the motor speed control circuit, replaced this and the volume motor was functional again. Did some mandatory checks to see if the protection kicked in, when the amp was exposed to the relevant circumstances and got positive results for each test. After all this, ran the amp for 500 hours, day and night playing a high volumes as well as at low volumes. Did some minor servicing on the soft clipping switch to get it to work, checked complete functionality using both remote and manual operation, cleaned all the input sockets, tightened up all the screws, removed some dents from the top cover, screwed it all up and shipped it back. I hope FM jmascreen enjoys this amplifier for many years to come.