The quest was for a “reasonably priced” published 3-way floorstander design, and the two that made the shortlist were Tarkus, and Troels Gravesen's SBA 861 PFCR.

Tarkus appears reasonably well received and considered a bargain considering the low cost. There aren't any real-world reviews for the SBA861, I couldn't find any. I'll save that design for another day, although it is a much less complicated cabinet to execute.

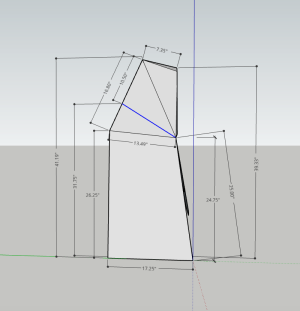

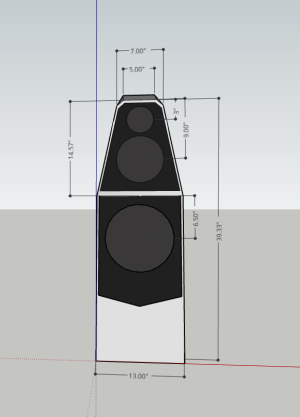

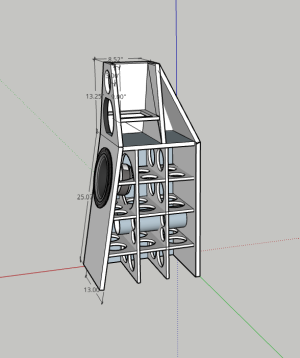

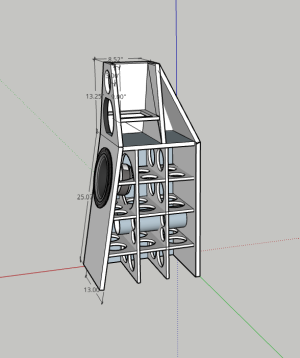

I also liked that the Takus design was flexible as long as the driver distance and the cabinet volume were maintained. The Wilson-esque design appealed to me the most, and I quickly learnt to use SketchUp to draft a mockup. I didn't muster the best sketch, but getting there.

Here's the draft: The outer shell will be 18mm MDF, and the bracing 12mm.

I have zero experience or knowledge to assemble the crossover. I shall try nonetheless. Anything I should know before I go ahead and purchase the drivers?

Tarkus appears reasonably well received and considered a bargain considering the low cost. There aren't any real-world reviews for the SBA861, I couldn't find any. I'll save that design for another day, although it is a much less complicated cabinet to execute.

I also liked that the Takus design was flexible as long as the driver distance and the cabinet volume were maintained. The Wilson-esque design appealed to me the most, and I quickly learnt to use SketchUp to draft a mockup. I didn't muster the best sketch, but getting there.

Here's the draft: The outer shell will be 18mm MDF, and the bracing 12mm.

I have zero experience or knowledge to assemble the crossover. I shall try nonetheless. Anything I should know before I go ahead and purchase the drivers?

Last edited: