You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 Way Speakers with Separate Enclosures for Bass & Mids

- Thread starter sadik

- Start date

Update.

First is, I bought a new 3M Reusable Respiratory Mask. A very good quality, it will be usful for all applications like Sanding, Cutting MDF / PLY, Painting... etc.

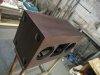

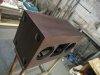

So now the sanding is completed and ready for stain.

I have attached a Foam (mostly used in Packing) on the top of the table to prevent the bottom wall from getting damaged. As this will be temporary i have used double sided tape for attaching this Foam. As seen in below Photos.

Below are the photos before & after applying stain.

After

Now Clear Coat will be applied tomorrow.

Sadik

First is, I bought a new 3M Reusable Respiratory Mask. A very good quality, it will be usful for all applications like Sanding, Cutting MDF / PLY, Painting... etc.

So now the sanding is completed and ready for stain.

I have attached a Foam (mostly used in Packing) on the top of the table to prevent the bottom wall from getting damaged. As this will be temporary i have used double sided tape for attaching this Foam. As seen in below Photos.

Below are the photos before & after applying stain.

After

Now Clear Coat will be applied tomorrow.

Sadik

+1 on the respirator, are you using ply backed veneer, paper veneer or fleece backed? I prefer paper veneer, trouble is finding good glue for that unless you have a vacuum press, even though it's available no one will sell to small businesses or DIY guys.

This is 4mm veneer sheet glued with 24mm Action TESA HDHMR sheet. It is glued with Fevicol SH & Press fitted on a 100 Ton Press machine & left overnight for drying under pressed condition.

keith_correa

Well-Known Member

I don't understand. You stained the veneer, applied Clear Coat and now are going to apply polish over Clear Coat? What was the point of applying Clear Coat?

This is a different kind of Polish with my own personalized process.I don't understand. You stained the veneer, applied Clear Coat and now are going to apply polish over Clear Coat? What was the point of applying Clear Coat?

Thank You @tuffLooks beautiful.

Update:

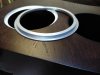

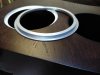

CNC machined Interlocks with Rubber Rings to Damp Vibrations as well as firm Grip. Size is 48 mm Diameter & 25 mm Height

As it can be seen in above photo the outer ring has a firm grip on the diameter of slot It will prevent any kind of sideways moment where as the small rubber ring on the Top & Bottom face will prevent the metal contact with the enclosure. These rubber rings will also help to absorb vibrations

Sadik

CNC machined Interlocks with Rubber Rings to Damp Vibrations as well as firm Grip. Size is 48 mm Diameter & 25 mm Height

As it can be seen in above photo the outer ring has a firm grip on the diameter of slot It will prevent any kind of sideways moment where as the small rubber ring on the Top & Bottom face will prevent the metal contact with the enclosure. These rubber rings will also help to absorb vibrations

Sadik

D

Deleted member 91806

Guest

Very interesting , would love to see the final outcome!Its been a quite long time since I last shared my Projects on our Forum. So now i am up with something Big. I can say it will be a monster.

I am up with a new project a 3 way tower with Three Individual enclosures stacked one above another. Interlocking is provided so the enclosures wont slip off & Isolation is provided for interlock joint to absorb the vibrations and prevent any kind of rattling noise, Image of same will be shared later once i have them in my hand.

So moving ahead, The Bottom Enclosure will be Bass, Middle will be for Mids & Highs & again top will be for Bass. Like the below image for better understanding. Total Height will be more than 7ft.

I don't wanna disclose much about the drivers so i will not mention any details about it except for their sizes. The Bass driver will be 15 Inch, Mids will be 10 Inch & Highs will be Ribbon Horn

I have chosed HDF as the construction material having thickness 25mm, The Finish enclosure will be veneered. I have chosen a off white shade veneer and decided later to stain it with our choice of shade. The Veneer is glued to HDF before cutting. It was glued & then pressed on a 100 TON hydraulic press and left overnight for the glue to dry. Its like 10 trucks stacked one above the other on the glued sheet.

Below are photos of Cutting on CNC router

The 45 Deg cut on the edges to match the flow of veins of veneer on all sides will be done with circular saw. This job will require a great precision and will need jig to achieve the accuracy it need. And yes Challenge accepted Because I know i can do it.

I will share the image of Jig soon.

Sadik

Sanjeev Kumar

New Member

Thank You Bro,

The Crossover is designed, but yet to be made.

Below is the Photo of the cutting blade i am using. This Blase is used to cut aluminum sections.

The marking Jig which i mentioned in my first post.

Below is the video how i am using it. it will save huge amount if my time.

The Demo Wooden panel in Short the Final results. This chamfer will be done to all the six panels of the enclosure. In total there are 6 Enclosures ... so lot of work to do. I will start the actual work from tomorrow.

Sadik

W

Dear Sadik do you have in-house facility of 100 ton press facility or outsourcedThis is 4mm veneer sheet glued with 24mm Action TESA HDHMR sheet. It is glued with Fevicol SH & Press fitted on a 100 Ton Press machine & left overnight for drying under pressed condition.

W

Dear Sadik do you have in-house facility of 100 ton press facility or outsourced

It is outsourced.

Lalrinzuala

Member

great work. I am both into woodworking and audio. So i have a few query.

1. From where do you sourced your audio components.

2. And from where do you get your veneer. Is it available online.

as i am from the remotest of region in India, online sourcing is usually my only option

1. From where do you sourced your audio components.

2. And from where do you get your veneer. Is it available online.

as i am from the remotest of region in India, online sourcing is usually my only option

great work. I am both into woodworking and audio. So i have a few query.

1. From where do you sourced your audio components.

2. And from where do you get your veneer. Is it available online.

as i am from the remotest of region in India, online sourcing is usually my only option

Audio Components mostly from online sites which i have mentioned below.

1. THE AUDIO CRAFTS

2. AUDIOFY

3. ELECTROCARTS

4. DIY AUDIO CART

& for Veneer i purchase it locally.

Lalrinzuala

Member

Thanks for the information sirAudio Components mostly from online sites which i have mentioned below.

1. THE AUDIO CRAFTS

2. AUDIOFY

3. ELECTROCARTS

4. DIY AUDIO CART

& for Veneer i purchase it locally.

The Mid Enclosures are almost complete. A little bit of fine grit sanding with 600 or 1000 grit paper and a clear matt coat and the job is done.

There are some Braces of Speaker enclosure on the Table at the backside seen in above photo, Yep, its another Project running parallel. A three way Mamoth with 18 Inch Sub, 10 Inch Mid and a Compression Drive with horn.

Sadik

There are some Braces of Speaker enclosure on the Table at the backside seen in above photo, Yep, its another Project running parallel. A three way Mamoth with 18 Inch Sub, 10 Inch Mid and a Compression Drive with horn.

Sadik

Passive_audio_enthusiast

Well-Known Member

The finishing on this work is very impressive.

Update:

Its 1Month+ and i have not updated in this built. The MIDS enclosures were delivered to the client and I have today started to finish the bass enclosures. I have made an aluminum ring which will be fitted on the vent mouth to improve the aesthetics. This ring is made on CNC machine it will be colored black.

For fitment of this ring i had made a special tool for my router. This Bit is made to order as per my requirement.

The plunge attachment of this router is soo good it works like a charm. If anyone want my advise to buy a router. This is my recommendation buy it with your eyes closed.

Its 1Month+ and i have not updated in this built. The MIDS enclosures were delivered to the client and I have today started to finish the bass enclosures. I have made an aluminum ring which will be fitted on the vent mouth to improve the aesthetics. This ring is made on CNC machine it will be colored black.

For fitment of this ring i had made a special tool for my router. This Bit is made to order as per my requirement.

The plunge attachment of this router is soo good it works like a charm. If anyone want my advise to buy a router. This is my recommendation buy it with your eyes closed.

Wharfedale Linton Heritage Speakers in Walnut finish at a Special Offer Price. BUY now before the price increase.

Similar threads

- Replies

- 24

- Views

- 9K