You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My DIY Enclosures - Common Thread for all my Enclosures

- Thread starter sadik

- Start date

Yelamanchili manohar

Well-Known Member

Lovely build of those gorgeous looking wave guides. Dont mean to hijack the thread...but can you please elaborate a bit on these horns. The frequency range, efficiency and compression driver used etc. Not everyday that we get to see horns around hereSadik has done an awesome job with these waveguides..

Here is a pic of the waveguide resting on top of a cabinet housing 2 x Satori WO24P 9.5inch woofers (just for scale)..

View attachment 83545

Vineethkumar01

Well-Known Member

Thanks..Lovely build of those gorgeous looking wave guides. Dont mean to hijack the thread...but can you please elaborate a bit on these horns. The frequency range, efficiency and compression driver used etc. Not everyday that we get to see horns around here

These are the EXAR 400 horns from Marcel Batik (mabat on diyaudio). It accommodates 1inch compression drivers

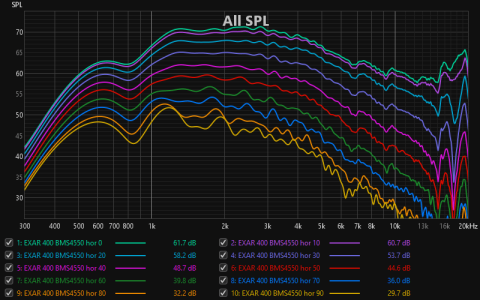

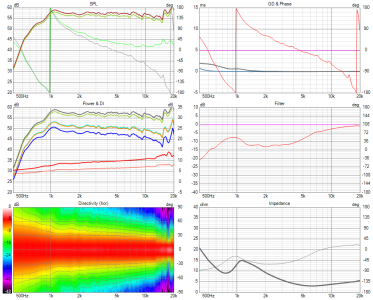

Here are my polar measurements of a 1-inch BMS 4550 on this horn (raw responses)

My plan is to also try out this horn with the SB Audience Rosso 65 1.4inch CD with a custom 1inch adaptor designed by mabat.

Measurements taken 1m away from horn mouth (gated at 4.1ms)

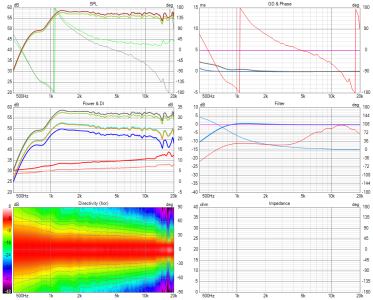

On axis frequency response and impedance measurement together

VituixCAD plots

Normalized directivity computed with reference axis as 10 degrees off axis

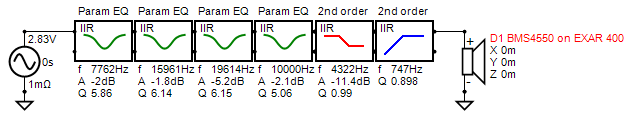

Here is what a rough active filtering on this horn can do

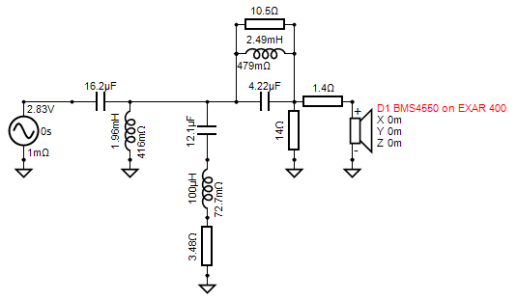

And here is a rough first-cut passive filter

Yelamanchili manohar

Well-Known Member

Thanks for sharing...the measurements look sweet. And a wide range of 800 to 20k is excellent to have without any crossovers in between. All the best to trying out the CD with the throat adapter.Thanks..

These are the EXAR 400 horns from Marcel Batik (mabat on diyaudio). It accommodates 1inch compression drivers

The frequency range can probably be anywhere from 800Hz to 20kHz depending upon the system configuration.

Here are my polar measurements of a 1-inch BMS 4550 on this horn (raw responses)

My plan is to also try out this horn with the SB Audience Rosso 65 1.4inch CD with a custom 1inch adaptor designed by mabat.

Measurements taken 1m away from horn mouth (gated at 4.1ms)

View attachment 83568

On axis frequency response and impedance measurement together

VituixCAD plots

Normalized directivity computed with reference axis as 10 degrees off axis

Here is what a rough active filtering on this horn can do

View attachment 83569

View attachment 83570

And here is a rough first-cut passive filter

View attachment 83571

View attachment 83572

Due to health issues (lower Back Pain) i am a bit slower on my builds, I have a total of 4 Projects which were yet to be completed, I really appreciate the patience of my clients who had given me the opportunity to make their enclosures, They have given me lot of time to complete their enclosures. I didn't touched a single tool or a piece of wood for about a month. And i have decided to take a break after completing all the 4 Projects. 1 of them is completed which are small Bookshelf enclosures and there are 3 more pending. Here are some Photos of same.

Earlier it was decided to color the enclosure completely, but the grains of Birch wood turned out so nice that client insisted for a dark stained Rosewood polish, and top coat is clear Matt PU paint.

Earlier it was decided to color the enclosure completely, but the grains of Birch wood turned out so nice that client insisted for a dark stained Rosewood polish, and top coat is clear Matt PU paint.

Due to health issues (lower Back Pain) i am a bit slower on my builds, I have a total of 4 Projects which were yet to be completed, I really appreciate the patience of my clients who had given me the opportunity to make their enclosures, They have given me lot of time to complete their enclosures. I didn't touched a single tool or a piece of wood for about a month. And i have decided to take a break after completing all the 4 Projects.

Take care and get well soon and come back all hale and hearty. wishing you the very best !

ponomariev

New Member

They look beautiful indeed!

What do you use as grill fabric?

What do you use as grill fabric?

oldmonk

Well-Known Member

Do show us the drivers..Another Project Completed Slowly and Steadily.

View attachment 86724View attachment 86725View attachment 86726View attachment 86727View attachment 86728

These look like an MTM configuration?

Thankyou Sameer Bhai.Love them ! Beautiful Sadik !

Thankyou. Its Grill Cloth you can get it from The AudiocraftsThey look beautiful indeed!

What do you use as grill fabric?

Its Full Range Driver. The Driver is Mark Audio MAOP11.2. & Enclosure is MLTLDo show us the drivers..

These look like an MTM configuration?

mantu

New Member

Once again, very good job done!

Manoj Nair

Member

Superb ...Very niceHi Friends, Now a days I am not very active on hifivision, In fact I am not getting enough time to document my built journey so I thought of at least make a thread where I can share the photos of the complete enclosures. So from now on I will be posting photos of all my enclosure projects in this thread.

So the First post in this thread are custom designed enclosures, they are huge with external dimensions as 1280 (H) x 380 (W) x 420 (D)

These enclosures are RAW finish. (No Veneer, No Putty work, no Primer no Sealer no clear just RAW enclosures and Shellac Polish). One of my hardest project till date because I had to take great precautions during cutting and assembling them. The DIY guys may be very well aware of cutting plywood in the opposite grains, The Plywood gets chip off while cutting along opposite grains of wood. A slight chip off will ruin the complete look of enclosures.

Lets enjoy some final built photos of enclosures

View attachment 82262View attachment 82263View attachment 82264View attachment 82265View attachment 82266View attachment 82267View attachment 82268View attachment 82269View attachment 82270View attachment 82271

While taking up this project i had discussed with user and made it clear about all the difficulties which may occur in the enclosures, (like chipping of plywood while cutting in opposite grains of wood, some air pockets in the internal of plywood after cutting, or may it be some dents on surface of plywood etc) he also understood the same and gave me green signal to go ahead and make the project happen. Secondly making grill is not my cup of tea but still i manage to make a good looking grill and for such a huge enclosure the grill was also another task.

But in the End this Project turn out to be a Master Piece. Next Project is soon on the way... Stay tuned.

Get well soon Sadik bhai!Due to health issues (lower Back Pain) i am a bit slower on my builds...

And needless to say great builds!

Order your Rega Turntables & Amplifiers from HiFiMART.com - India's reputed online dealer.

Similar threads

- Replies

- 29

- Views

- 7K