Progressing but slow. .

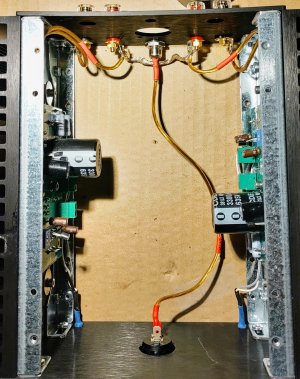

Chassis is a bit of a pain to assemble with screws from inside and all sides need to level. Slotted holes do help to level them. Fixed the top panel to keep the heatsinks level and adjusted the front and back panels and removed the top for wiring access.

In construction industry we say not to tighten the screws in one go..put in all structural members, keep screws a bit loose, level and then tighten screws diagonally one by one..that worked here.

It'd have been better with screws from outside connecting front panel and back panel to heatsink.Tapped in holes on the heatsink for front and back panels as well and top and bottom would have been better than the steel frames provided.

Next unit will have the top panel fitted first to both heatsinks and then the front and back panels.

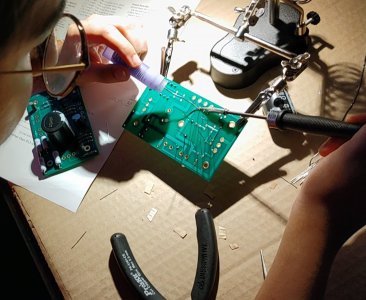

Had fitted the PCBs on heatsink while soldering the MOSFETs. Did not want to dismantle so as not to disturb the devices. The output cap is coming in the way to tighten the front panel screws.

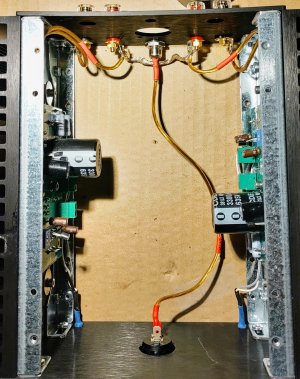

Rear bottom row accessories done and wired.

@Kannan have put in Phoenix screw connectors for power and LED. Plugin type have different pitch so cannot go in. Molex not available locally.

Used salvaged speaker wires (from my old Jamo internal guts) for output wiring and main DC than what has been given in the kit.

LEDs wired with a piece from ribbon cable that was lying around. LEDs holes on front panel are way too big..had to shrink some sleeves around the LEDs to keep them from falling off. When doing a CNC work is it difficult to make the hole size to LED dimensions or all LEDs not of same size

?

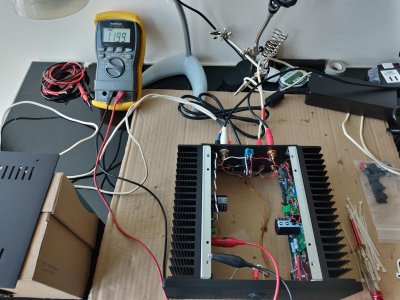

DC to PCBs and input RCAs, XLR wiring balance. Hope to make it sing today.