You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

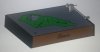

Lenco rebuild with ARO Naim

- Thread starter Beginner_N

- Start date

Beginner_N

Well-Known Member

Beginner_N

Well-Known Member

shafic

Well-Known Member

How are making it Bro ??I have just started my journey, my first step towards turntable. Below is my completed drawing of Plinth for Lenco L-75. The Process has just started.

Sadik

Plastic moulding, 3D printing etc ??!

Beginner_N

Well-Known Member

I would suggest PTP. It's pretty simple.

I would suggest PTP. It's pretty simple.

What is PTP?

Beginner_N

Well-Known Member

Peter's top plate. The way I did for my lenco.

Beginner_N

Well-Known Member

very nice ! you seem to be using the PTP6. I am pretty sure the Naim Aro would be a fantastic combination with this !

One suggestion, wind some plumbing tape around the idler wheel arm to damp vibrations.

Is that a brass front plate ? I am looking for a brass or golden colored plate like this ( custom dimensions). Not particular about thickness and even 1-2mm are fine. Any pointers ?

One suggestion, wind some plumbing tape around the idler wheel arm to damp vibrations.

Is that a brass front plate ? I am looking for a brass or golden colored plate like this ( custom dimensions). Not particular about thickness and even 1-2mm are fine. Any pointers ?

reubensm

Well-Known Member

what lovely work, quick query - would the idler constantly engage with the platter rim or have you factored in the on/off lever?

Beginner_N

Well-Known Member

very nice ! you seem to be using the PTP6. I am pretty sure the Naim Aro would be a fantastic combination with this !

One suggestion, wind some plumbing tape around the idler wheel arm to damp vibrations.

Is that a brass front plate ? I am looking for a brass or golden colored plate like this ( custom dimensions). Not particular about thickness and even 1-2mm are fine. Any pointers ?

Thank you!. Will use teflon tape on idler wheel arm. Its PTP 6 copy.

Naim ARO is on shelf, not finding good machining guy who can work on my tolerances, small size parts, quantity that 1 and price which is affordable. But I keep sending it for quotation, never know someone might do it. I will be using Ortofon SMG 212.

Its SS front plate laser cut. Brass sheets are available in 2mm.

Regards,

Nishant

Beginner_N

Well-Known Member

what lovely work, quick query - would the idler constantly engage with the platter rim or have you factored in the on/off lever?

Thank you!

It will be in constant touch with platter.

Beginner_N

Well-Known Member

Finally Lenco is singing. So satisfying...

Now painting and polishing. Tone arm SMG 212. Then will do final setup.

Now painting and polishing. Tone arm SMG 212. Then will do final setup.

Last edited:

Beginner_N

Well-Known Member

Thanks Sadik!Congrats Bro....

Beginner_N

Well-Known Member

Buy from India's official online dealer!