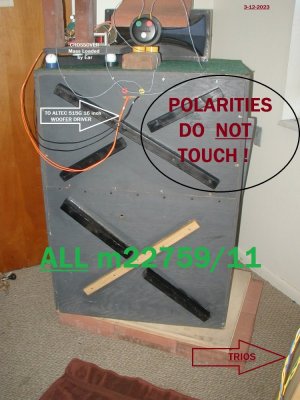

My approach has been to use the same wire from amp to speaker as that was used within the speaker to wire the drivers which is approx 12AWGIt is good to learn what you posted. I just looked up your Cadence speaker. A seven inch driver with a ESL panel ( nicely ) time-aligned positioned on top, crossed over at 1.8 kHZ. With a rated efficiency of only 86.5 dB, I would like to suggest that 14 and 16 AWG will not be the best solution, to optimally couple electrical energy from your P-P 40 Watt 6550 amplifier to your speaker. The TRIO wiring in this thread, is the equivalent of 8 AWG, and over four decades, that is about what I have found is needed to ideally couple any decent amplifier, to a decent speaker, to get full performance from the bass notes on up.

Developing an 8 AWG wire for audio use is quite a challenge, as we want the cable to be wideband at both extremes of the sound spectrum, but be balanced and natural sounding. Not just play the midrange. The TRIO, DIY built as I described it herein, is the only approach I am aware of, that fits the requirement. Its been user tested - 10 for 10......... in decent systems.

My original post's query was, what was the AWG of the power cord braided you suggested, and what does it look like, the braid, etc.

BTW, off topic, but I am familiar with electrostats. In the 1970s, after I sold my first-purchased new speaker ( 15 inch Tannoy Monitor Golds in GRF factory enclosures ) I purchased used KLH Model 9s, advertised as a full range ESL. I later found a used second pair, and ended up running " double KLH9s", which back in the day was quite the audio "In" thing to do.

After the double KLH9s, I owned Infinity Systems " Servo Static 1" electrostatic , with upgraded "1A" ESL panels, and a large ( 18 Inch ? ) system sub woofer. That was mostly ESL in playback. In 1975, Gordon Holt of Stereophile Magazine gave them an " A" rating, along with the new " Fulton J Modular " large loudspeaker,......... JUST those two speakers. I became associated with Robert Fulton, until he passed away in 1988.

Here is a photo of me picking up what was to be my second pair of KLH9s, early 1970s, on Venice Blvd., in Venice, CA, a town in the Los Angeles, CA area. I sure was happy and excited-looking, anticipating usage of that second pair. Having a convertible vehicle ( a 1961 356B Roadster ) , helped fit-them-in for a short journey home.

( Gee, the KLH9 transport-photo is in Adobe Acrobat, and I can not get it to paste here, in that form. I WILL TRY TO GET A COMPUTER SAVVY AUDIOPHILE FRIEND TO HELP GET IT IN A BETTER FORMAT. CUTE PHOTO for sure. )

Jeff

The world of electrostatics is a different one. For me its “till death do us part” kind of a relationship, well and truly hooked.

That roadster I like