rajagopal_j

Active Member

It has been eons since I have actively posted on this forum and I thought it will be fun to get back with documenting this build here.

I have been quite settled with my setup for well more than 10 years now, I think I did a build thread then, I am not sure if its still there. Maybe I should update and do an evolution of my setup over time from open baffles to bass reflex. Anyway while a lot has changed since then some primary components remain, I have had my 425Hz LeCleach .707 hypex horns as the primary horn for more than 10 years now. While making these I did spend time reading JM LeCleach's work and I found that in one of his comparisons he found the Klangfilm Spherical wavefront horns aka Kugelwellen horns to be the best, I have always wanted to make one of those since then.

Fast forward 10+ yrs to about 2 weeks back and I realised I still want to make one. I own a 3D printer (actually 2 printers) so why not! Fire up a dev env and lets code. The idea is to make a 500Hz Kugelwellen horn with a .75 eccentricity for dispersion with a built in filleted flange at the throat to fit it on to my HF driver.

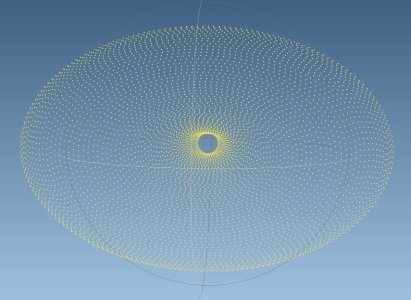

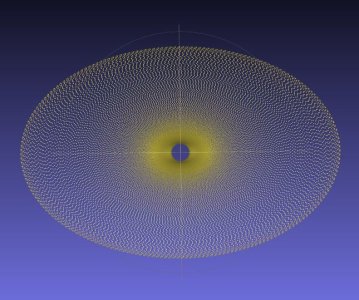

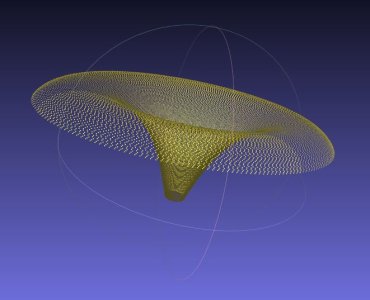

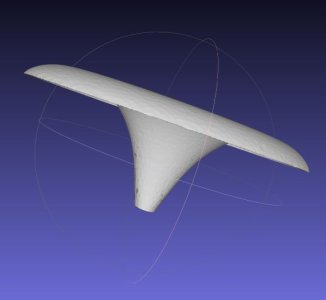

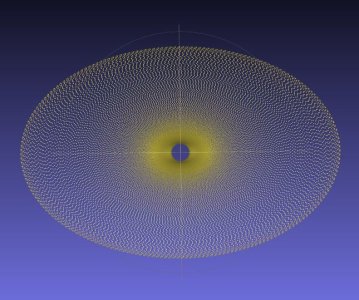

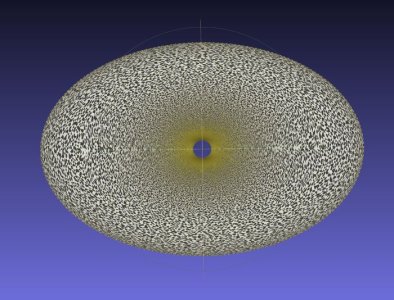

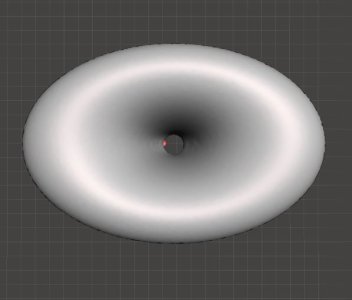

First plot the wave front propagation based on the horn params and get a point cloud

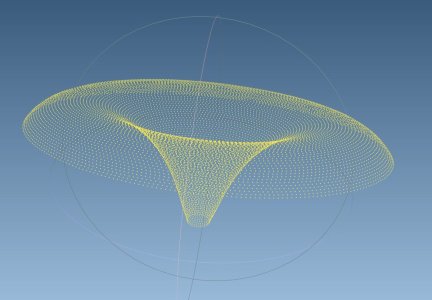

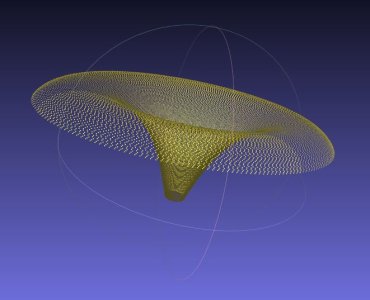

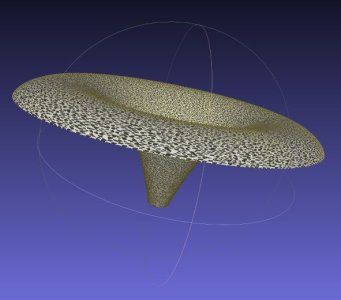

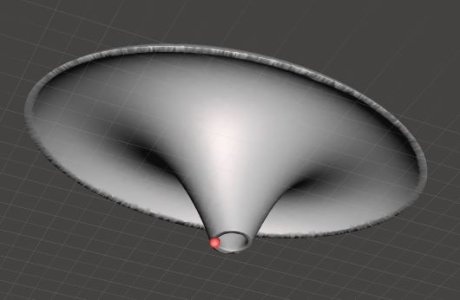

Next, draw triangles and form the shape to make a mesh

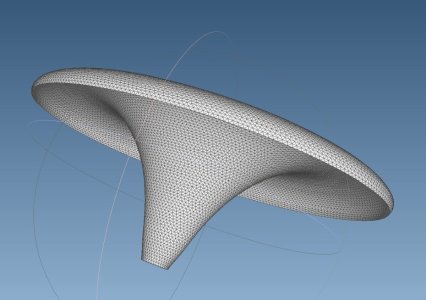

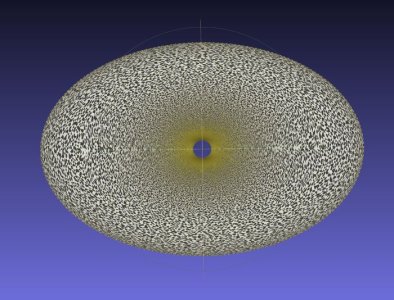

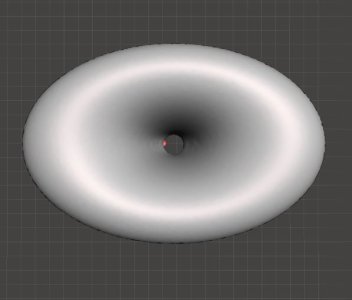

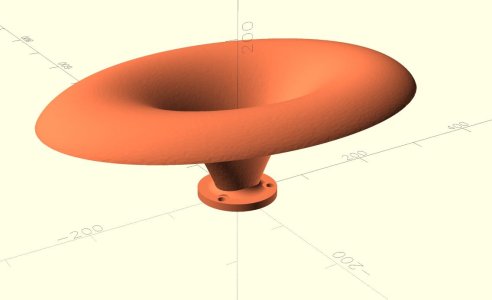

Now lets wrap it

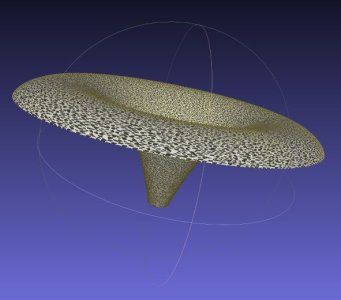

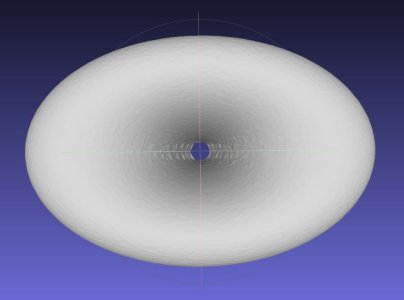

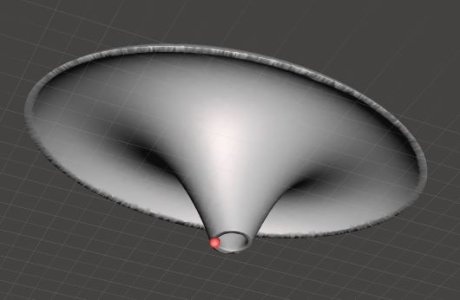

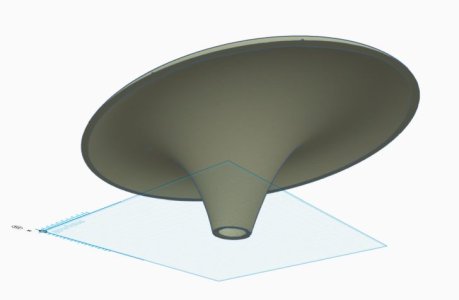

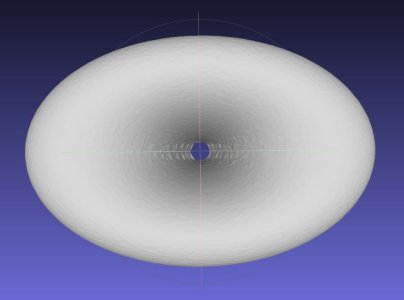

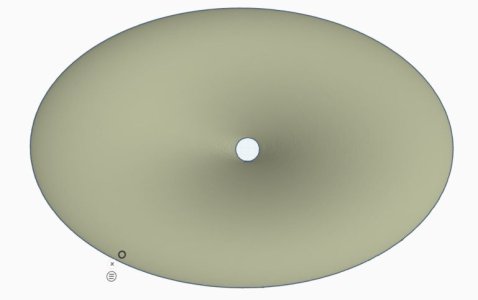

This mesh while it looks solid, still doesn't have a thickness, so extrude the outer face and add thickness

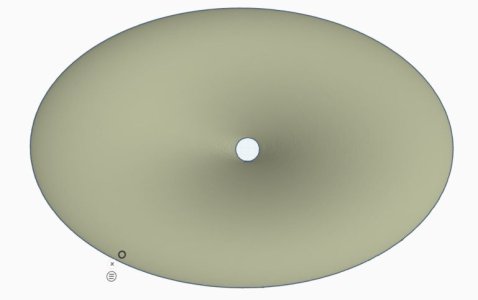

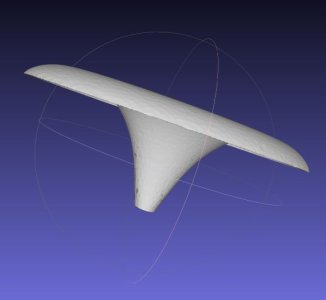

The edges are not clean, so clean up in TinkerCad

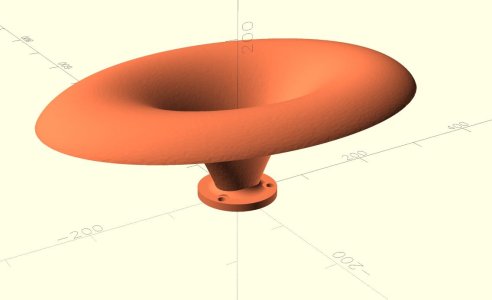

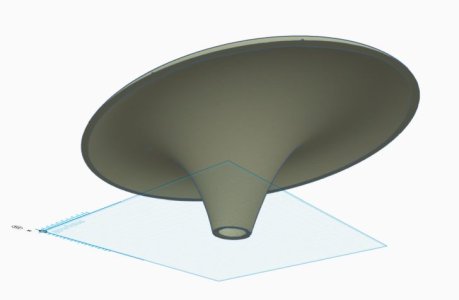

We need a way to mate with with the HF driver so, Add a mounting Flange and fillet joint for strength in OpenScad

Finally time to print, but it has to be split into 2 pieces to fit the bed.

Next to the current LeCleach horn to give a better idea of size. The LF is 15 incher, the LeCleach horn is ~16in in diameter.

Now for the most painful part of this build sanding, priming, welding the halves and painting. The inside profile has to be super smooth. Lots of work done, a lot more to do!

More as I make progress!

I have been quite settled with my setup for well more than 10 years now, I think I did a build thread then, I am not sure if its still there. Maybe I should update and do an evolution of my setup over time from open baffles to bass reflex. Anyway while a lot has changed since then some primary components remain, I have had my 425Hz LeCleach .707 hypex horns as the primary horn for more than 10 years now. While making these I did spend time reading JM LeCleach's work and I found that in one of his comparisons he found the Klangfilm Spherical wavefront horns aka Kugelwellen horns to be the best, I have always wanted to make one of those since then.

Fast forward 10+ yrs to about 2 weeks back and I realised I still want to make one. I own a 3D printer (actually 2 printers) so why not! Fire up a dev env and lets code. The idea is to make a 500Hz Kugelwellen horn with a .75 eccentricity for dispersion with a built in filleted flange at the throat to fit it on to my HF driver.

First plot the wave front propagation based on the horn params and get a point cloud

Next, draw triangles and form the shape to make a mesh

Now lets wrap it

This mesh while it looks solid, still doesn't have a thickness, so extrude the outer face and add thickness

The edges are not clean, so clean up in TinkerCad

We need a way to mate with with the HF driver so, Add a mounting Flange and fillet joint for strength in OpenScad

Finally time to print, but it has to be split into 2 pieces to fit the bed.

Next to the current LeCleach horn to give a better idea of size. The LF is 15 incher, the LeCleach horn is ~16in in diameter.

Now for the most painful part of this build sanding, priming, welding the halves and painting. The inside profile has to be super smooth. Lots of work done, a lot more to do!

More as I make progress!