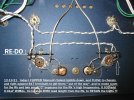

12- 11 -2021 Mini Photo Update ............ Ground BUSS, ........... Each Channel - to STAR Central Ground

12 AWG Mil Spec wire, Teflon jacket stripped- off below photo. Beautiful quality silver plated copper stranded wire, leading to STAR GROUND, the central chassis brass bolt.

ON RCA Input Jacks : " Delicious sounding " 430K Shinkoh TAF half Watt tantalum resistors, best sounding resistor brand of six different resistor types we tried. ( start out - on the right foot !! ). Shinkoh tantalums are no longer manufactured.

Notice how bare 12 AWG Mil Spec ground buss wire crosses the chassis filament wires, not touching AND at 90 degrees for minimal interference.

Thank you - for looking.

Jeff

12 AWG Mil Spec wire, Teflon jacket stripped- off below photo. Beautiful quality silver plated copper stranded wire, leading to STAR GROUND, the central chassis brass bolt.

ON RCA Input Jacks : " Delicious sounding " 430K Shinkoh TAF half Watt tantalum resistors, best sounding resistor brand of six different resistor types we tried. ( start out - on the right foot !! ). Shinkoh tantalums are no longer manufactured.

Notice how bare 12 AWG Mil Spec ground buss wire crosses the chassis filament wires, not touching AND at 90 degrees for minimal interference.

Thank you - for looking.

Jeff

Last edited: