Vineethkumar01

Well-Known Member

More Updated: Measurement session - part 2

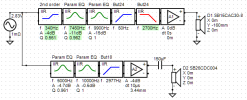

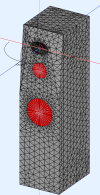

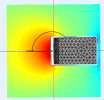

I have finally completed a prototype box with the baffle attached to it. The box size for the mid is currently about 10 L in volume. Using this, I have tried to do full 0 to 90 degree measurements in the horizontal plane on for both the mid driver SB15CAC30-8 and the tweeter SB26CDC004 i 4 inch waveguide. Looks like they came out well.

The tweeter in the waveguide looks too good. Now it is time to start thinking about building the actual enclosure.

In the meanwhile, I will use these measurements and VituixCAD to design a prototype crossover.

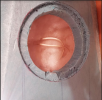

Pic-1 shows drivers on baffle

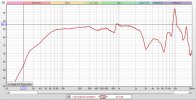

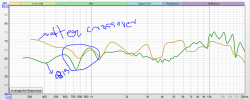

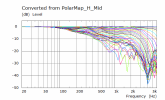

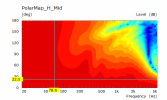

Pic-2 is the nearfield measurement of the mid

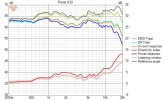

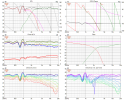

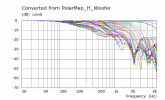

Pic-3 is the gated far field measurement set for mid (gate = 4ms)

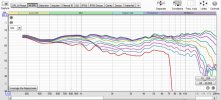

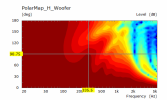

Pic-4 is the gate far field measurement data for tweeter (gate = 4ms)

Thanks

Vineeth

I have finally completed a prototype box with the baffle attached to it. The box size for the mid is currently about 10 L in volume. Using this, I have tried to do full 0 to 90 degree measurements in the horizontal plane on for both the mid driver SB15CAC30-8 and the tweeter SB26CDC004 i 4 inch waveguide. Looks like they came out well.

The tweeter in the waveguide looks too good. Now it is time to start thinking about building the actual enclosure.

In the meanwhile, I will use these measurements and VituixCAD to design a prototype crossover.

Pic-1 shows drivers on baffle

Pic-2 is the nearfield measurement of the mid

Pic-3 is the gated far field measurement set for mid (gate = 4ms)

Pic-4 is the gate far field measurement data for tweeter (gate = 4ms)

Thanks

Vineeth