You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pass B1

- Thread starter sachu888

- Start date

stereorules

Active Member

9.5mm dia it is then

i have a 9.6mm drill too if reqd

clean faceplate ... okie

just for my info ... volume pot will normally be on the RHS extreme ?

i will post a pic of the PDF'sso everyone can have a view and know what they are getting or give advice etc

Just a quick question ...

I'm planning to have an additional input selector inside ..The pcb is 4''x2'' ...I'm planning for 4 inputs on the back plate ..On the faceplate, I would need an input selector switch in addition ...

So do I need to drill holes for additional parts once I get the enclosure or u will do it ? Since the enclosure will be anodised and sent, can I drill additional holes ? or will it affect ? do the holes need to be drilled with a lathe or just normal drill ?

Thanks for update. Your complements are conveyed to my brother who watches this forum as a guest.Thanks Om, I received the R-Core Tranny today. Thank your brother as well for his efforts.

Thanks everybody for quick turnaround of money and patience. I got payment from almost everybody, remaining expected soon. That helps a lot!

I think all Bangalorians and personal takeaway got it, except Audiodoc and jetlag. I am watching for their packets.

Just a quick question ...

I'm planning to have an additional input selector inside ..The pcb is 4''x2'' ...I'm planning for 4 inputs on the back plate ..On the faceplate, I would need an input selector switch in addition ...

So do I need to drill holes for additional parts once I get the enclosure or u will do it ? Since the enclosure will be anodised and sent, can I drill additional holes ? or will it affect ? do the holes need to be drilled with a lathe or just normal drill ?

Hi, Can you send me exact rectangle size of PCB and hole positions with most accuracy? Just put that PCB on paper and measure. The draw these markings using paint and send as pdf. You know my email ID.

I am drawing the layout for base plate, front and rear plates. I will include some extra holes from considerations of future mods.

I will draw two options for each

rear plate - 4 inputs and 2 inputs

front plate - Source selection as toggle switch and rotary switch, volume control

base plate - considering partition in the layout all holes in M3 sizes.

Just a quick question ...

I'm planning to have an additional input selector inside ..The pcb is 4''x2'' ...I'm planning for 4 inputs on the back plate ..On the faceplate, I would need an input selector switch in addition ...

So do I need to drill holes for additional parts once I get the enclosure or u will do it ? Since the enclosure will be anodised and sent, can I drill additional holes ? or will it affect ? do the holes need to be drilled with a lathe or just normal drill ?

+1, I'm planning the same too.

Audiodoc

Well-Known Member

I am using the input selector switch with my pass BOZ which is a similar circuit using 2SK170s. Have a spare front plate with holes from a previous build.Will post pictures on the evening. Looking forward to how the cab group buy materializes.

sachu888

Well-Known Member

I am using the input selector switch with my pass BOZ which is a similar circuit using 2SK170s. Have a spare front plate with holes from a previous build.Will post pictures on the evening. Looking forward to how the cab group buy materializes.

Hi Doc,

Did you order JFETs?

Regards,

Sachin

stereorules

Active Member

I can send u a photo of the PCB and can tell you the dimensions ....then u can get exact idea of where the holes are .Hi, Can you send me exact rectangle size of PCB and hole positions with most accuracy? Just put that PCB on paper and measure. The draw these markings using paint and send as pdf. You know my email ID.

Audiodoc

Well-Known Member

Yes ordered a pair last night has already been shipped.

Just by thinking -

In pass B1 if people use two inputs and select one by using toggle switch then audio wires are moving away from PASS B1 board to front panel toggle switch. Contacts in toggle switch may be not that good. Why not add one 5V silver contact relay (like this) in that place control its on/off from front panel toggle switch?

Please express your thoughts.

In pass B1 if people use two inputs and select one by using toggle switch then audio wires are moving away from PASS B1 board to front panel toggle switch. Contacts in toggle switch may be not that good. Why not add one 5V silver contact relay (like this) in that place control its on/off from front panel toggle switch?

Please express your thoughts.

Just by thinking -

In pass B1 if people use two inputs and select one by using toggle switch then audio wires are moving away from PASS B1 board to front panel toggle switch. Contacts in toggle switch may be not that good. Why not add one 5V silver contact relay (like this) in that place control its on/off from front panel toggle switch?

Please express your thoughts.

The DCB1 (Mezmerize version) based on Pass B1 has that advantage. It takes 6 inputs based on such relays and has on board power supply.

sachu888

Well-Known Member

The DCB1 (Mezmerize version) based on Pass B1 has that advantage. It takes 6 inputs based on such relays and has on board power supply.

Yes,but It is better to have power supply on separate board IMO.

Regards,

Sachin

Yes,but It is better to have power supply on separate board IMO.

Regards,

Sachin

+1, power source should be non influencing to any audio board. That could be achieved simply by separating and isolating PS from main board. It avoids many unwanted noises and ground current which could impact performance. This care specially required for mains operated linear or switched PS, battery simplifies the handling but cumbersome in long run. Good PS is trouble to build at once but no need to look again into it.

Just by thinking -

In pass B1 if people use two inputs and select one by using toggle switch then audio wires are moving away from PASS B1 board to front panel toggle switch. Contacts in toggle switch may be not that good. Why not add one 5V silver contact relay (like this) in that place control its on/off from front panel toggle switch?

Please express your thoughts.

Switching through relays was always an option as it simplifies a lot of things. However the added wiring and switching operation itself introduces a lot of additional points. The Nelson Pass idea of keeping things simple gets defeated.

Finally it is all a matter of personal choices and various trade-offs,

Switching through relays was always an option as it simplifies a lot of things. However the added wiring and switching operation itself introduces a lot of additional points. The Nelson Pass idea of keeping things simple gets defeated.

Finally it is all a matter of personal choices and various trade-offs,

Agree! We need to think simple way of doing.

BTW I bought the DCB1 board from diyaudio store just for the sake of getting the hang on the DIY thing

Once I succeed with the B1 next to follow is the F5 build for which I bought the boards already being inspired from this thread :clapping:

Once I succeed with the B1 next to follow is the F5 build for which I bought the boards already being inspired from this thread :clapping:

jetlag

Member

Hi Om

Received the xfr today. Great packing. Thanks

Later

Jetlag

Received the xfr today. Great packing. Thanks

Later

Jetlag

Hi Om,

Thanks to you and Ram, got the packet safely. I must say I like the look of the Rcore. Been using Toroids all along and hopefully the performance also will be better....in any case I like the weight, rcore is much lighter...

Thanks once again for all the effort and co-ordination you have put into making this happen for us,

Gopi

Thanks to you and Ram, got the packet safely. I must say I like the look of the Rcore. Been using Toroids all along and hopefully the performance also will be better....in any case I like the weight, rcore is much lighter...

Thanks once again for all the effort and co-ordination you have put into making this happen for us,

Gopi

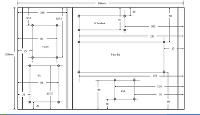

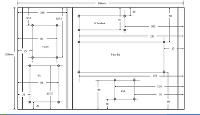

Directions from magma:

I prepared these plans, please look at these. I tried my best to match in-out holes on PCB with RCA locations at the back.

Also PCB mounting and R-Core holes are as per my handling in current project.

15mm partition and side walls, taken care. Mains Fuse, IEC socket and power switch dimensions are unknown. So they are missing.

Front:

Back-option1:

Back-option2:

Bottom-Plate:

please check the floor plan -

carpet area is 310mm width by 250mm depth ( deduct 15mm from 310mm if the seperater is used )

i need pdf with dimns for the faceplate which is 81*354mm and the rear plate which is 73*340mm

faceplate overhangs 4mm top and bottom and 7 mm on the sides

power IEC with switch is suggested to be on the left hand side when viewing the cab from the front ( faceplate view) and on the RHS if veiwing the back plate

I prepared these plans, please look at these. I tried my best to match in-out holes on PCB with RCA locations at the back.

Also PCB mounting and R-Core holes are as per my handling in current project.

15mm partition and side walls, taken care. Mains Fuse, IEC socket and power switch dimensions are unknown. So they are missing.

Front:

Back-option1:

Back-option2:

Bottom-Plate:

A beautiful, well-constructed speaker with class-leading soundstage, imaging and bass that is fast, deep, and precise.