initial observations

isint a 5mm LED hole too large - normally clients ask for 3mm - all you got to do is stick the LED behind the hole

3mm is enough for the light to shine thru

what one of my ingenious clients does is rest the faceplate on polythene

and then inject the hole with feviquick

this forms a transparent cover on the hole on solidifying

he then sticks the led behind the faceplate

Also the backplate option 2

you can shift the IN-1 holes BELOW the In-2 holes

in this way the out looks diff from the IN

plus the IN moves away from the PSU

Please note : i know nothing about electronic ckts - so the above may be dum advice

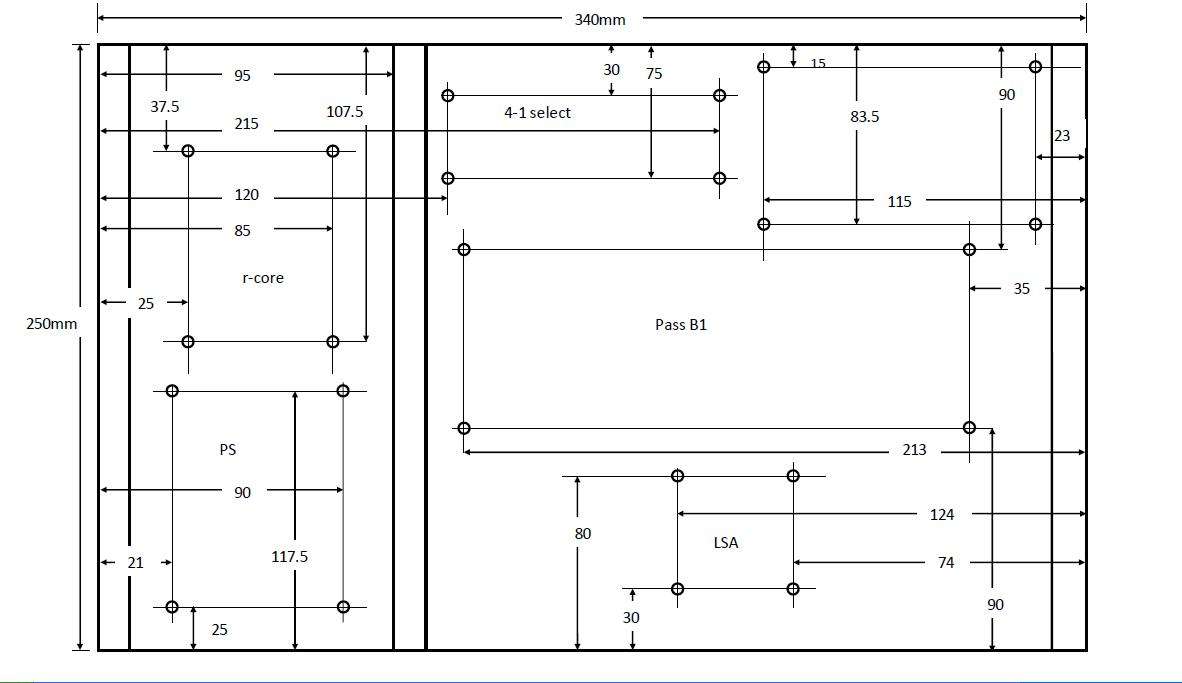

P.S - Om sir - hats off to you

those diagrams take a crap load of work!

i need to convert them to scale now - will have to say good morning to my dtp fellow

isint a 5mm LED hole too large - normally clients ask for 3mm - all you got to do is stick the LED behind the hole

3mm is enough for the light to shine thru

what one of my ingenious clients does is rest the faceplate on polythene

and then inject the hole with feviquick

this forms a transparent cover on the hole on solidifying

he then sticks the led behind the faceplate

Also the backplate option 2

you can shift the IN-1 holes BELOW the In-2 holes

in this way the out looks diff from the IN

plus the IN moves away from the PSU

Please note : i know nothing about electronic ckts - so the above may be dum advice

P.S - Om sir - hats off to you

those diagrams take a crap load of work!

i need to convert them to scale now - will have to say good morning to my dtp fellow

Last edited: